Quality Management

Quality is the foundation of why clients choose us. At ELOV, our Quality Management strictly adheres to all operational and ethical standards. We operate under a comprehensive quality management system, and every product undergoes rigorous inspection before it leaves our facility.

Certifications

ELOV has obtained numerous internationally recognized certifications related to quality control.

All certifications reflect not only the quality and reliability of our products but also serve as a strong guarantee for our customers. With extensive experience and proven expertise in the skincare manufacturing industry, ELOV is fully equipped to deliver products that meet the highest standards of safety and performance.

Reliable Quality Control You Can Trust

Sterile, Dust-Free Facilities for Safe and Hygienic Manufacturing

At ELOV, all production takes place in sterile, dust-free workshops to maintain the highest standards of cleanliness. Each day, our facilities undergo thorough cleaning and disinfection—both before production begins and after it ends. All equipment is also carefully cleaned by designated personnel after use to ensure a hygienic and well-maintained production environment.

Optimal Production Environment for Consistent Quality

At ELOV, we believe that a controlled environment is key to producing high-quality skincare products. Our production is carried out under carefully maintained conditions, with real-time adjustments to temperature and humidity to suit the specific requirements of each formulation. By ensuring an optimal production environment, we’re able to consistently deliver products that meet the highest standards of quality.

Protecting Product Integrity Through Rigorous Hygiene Standards

To prevent contamination and ensure product safety, everyone entering the factory must follow strict personal hygiene procedures. All exposed areas are disinfected, and dust-free garments are required. Before final entry, full-body disinfection is conducted. These rigorous hygiene protocols are in place to protect the integrity of our products and uphold the highest quality standards in manufacturing.

Thorough Disinfection of Packaging Materials

At ELOV, we take every step to ensure packaging materials are contamination-free. All suppliers are required to sterilize packaging before delivery. Upon arrival, materials are inspected by a dedicated warehouse manager and stored in a designated clean area. Before use, we perform a secondary disinfection to further ensure safety. These measures help us maintain the integrity and hygiene of every product we manufacture.

Complete Quality Testing at Every Stage

-

Ensuring Raw Material Quality from the Start

At ELOV, quality begins with raw materials. We verify supplier certificates and perform random inspections. All materials are stored in a clean area, ensuring every ingredient is safe, reliable, and consistent. -

Strict Quality Control for Semi-Finished Products

After processing, ELOV’s Quality Control team randomly checks formulations and ingredient ratios. We follow strict inspection rules to ensure every batch meets standards and is safe for users.

-

Final Product Inspection for Flawless Quality

We thoroughly inspect every finished product—from content to packaging—to ensure perfection. Our quality control team rigorously tests each item for safety, consistency, and quality.

Equipment Inspection

-

Emulsifying Machines

Our team is committed to ensuring the safety and purity of our products. We meticulously clean the emulsification equipment after each production run and perform regular maintenance.

-

Sealing Machines

Our sealing machines are thoroughly cleaned with specialised materials after extended use. This ensures they remain in optimal condition for continuous, reliable operation.

-

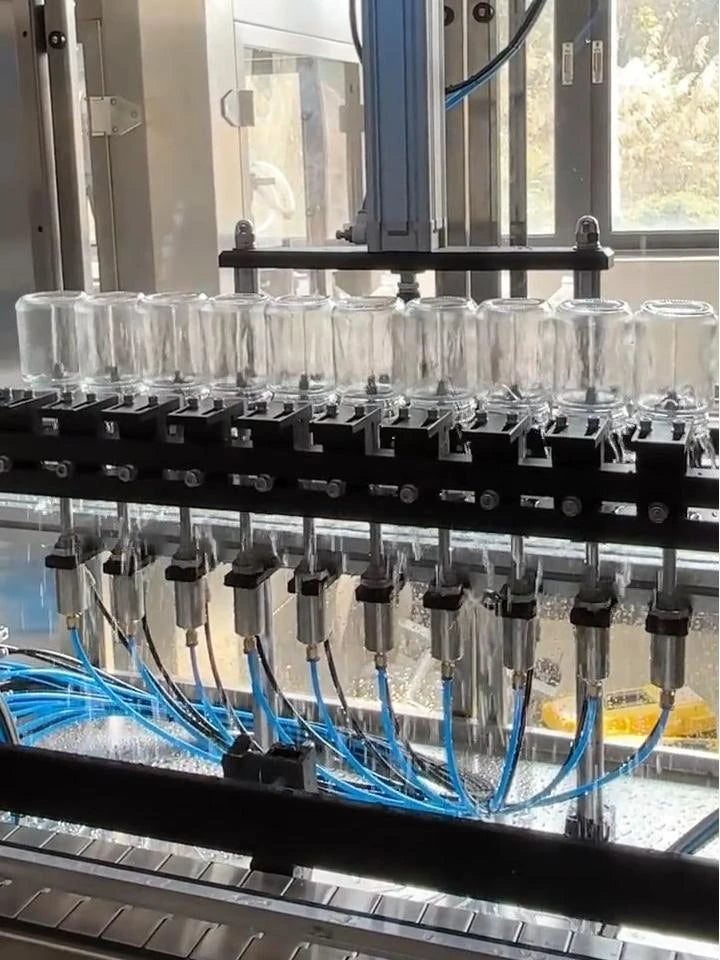

Filling Machines

Our automatic filling technology transfers liquids without staff contact, boosting accuracy, quality, and reducing contamination risks for safer skin products.

Trust-Building & Assuring

ELOV's implementation of a comprehensive product traceability system is instrumental in facilitating superior quality management. This system enables us to swiftly identify and rectify any defective products, thereby enhancing our after-sales service and continuous improvement initiatives. Each ELOV product is assigned a unique code that tracks it throughout the entire production cycle. Partnering with ELOV ensures the provision of safe, high-quality products that will enhance your market competitiveness.